Providing a Valuable Service

We are a leading cutting tools manufacturer and suppliers providing high quality with competitive price with high standardized products to the consumer with the most reliable services. ACCUSHARP is known for high quality standardized and customized products that are tailored for our customers.

Accusharp Cutting tools Specializes in re-sharpening and re-coating services for solid carbide tools, special tools, form tools etc. We provide the best possible solution to fulfil the desire of customers.

Accusharp is mostly known for High-quality product and customer satisfaction. Delivering a quality product to our customer in time.

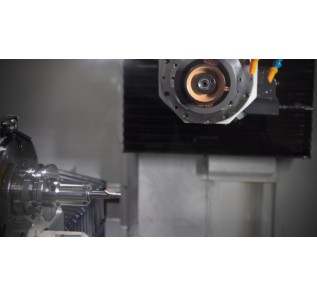

Accusharp tools are ground on rigid and high power with modern CNC equipment. Suitable, imported and world class quality diamond wheels are used for grinding the tools. Dimensional and surface quality norms on the tools are checked on Zoller Q.C. equipment

Accusharp cutting tools provide re-grinding & re-coating services for solid carbide tools, special tools, profile tools, etc. Accusharp offers a re-condition carbide brazed tools and carbide lugged tools. Restore Original Geometry. We also provide recondition services for other manufacturers in carbide cutting tools to its original geometry.

Pick-up Service Available. ACCUSHARP offers pick-up and delivery service for reconditioning in certain areas.

Accusharp re-sharpens your tools so that they can perform very well just like new tool.

Benefits:

The Future of PVD Coating Technology

Features denser coatings, improved hardness/toughness and enhanced cutting results – all with a deposition rate of 2 μm/h.

HiPIMS (High Power Impulse Magnetron Sputtering) is the next step in Sputter technology, combining all the advantages of the common coating technologies and methods currently on the market. HiPIMS produces smooth, droplet-free and

low-stress coatings in an almost unlimited variety.

With the smoothness of the sputtering, the high hardness values, compact coating structures and scratch resistance to over 130 newtons, tools coated in this way are exceptionally resistant to wear in extremely hard, especially tough and

oxidation-resistant materials such as stainless steel, titanium or nickel-based alloys.

But HiPIMS coatings can also deliver top performance in unalloyed, alloyed and high-speed steels. The high metal ionisation of nearly 100 per cent gives the best adhesion, even in cold-welded materials, which are particularly difficult

to machine. In addition, coatings deposited by HiPIMS technology give extremely homogeneous surfaces, even on very complex 3D geometries.

Benefits:

Some examples of best in-class coatings: