Features

Application

Description

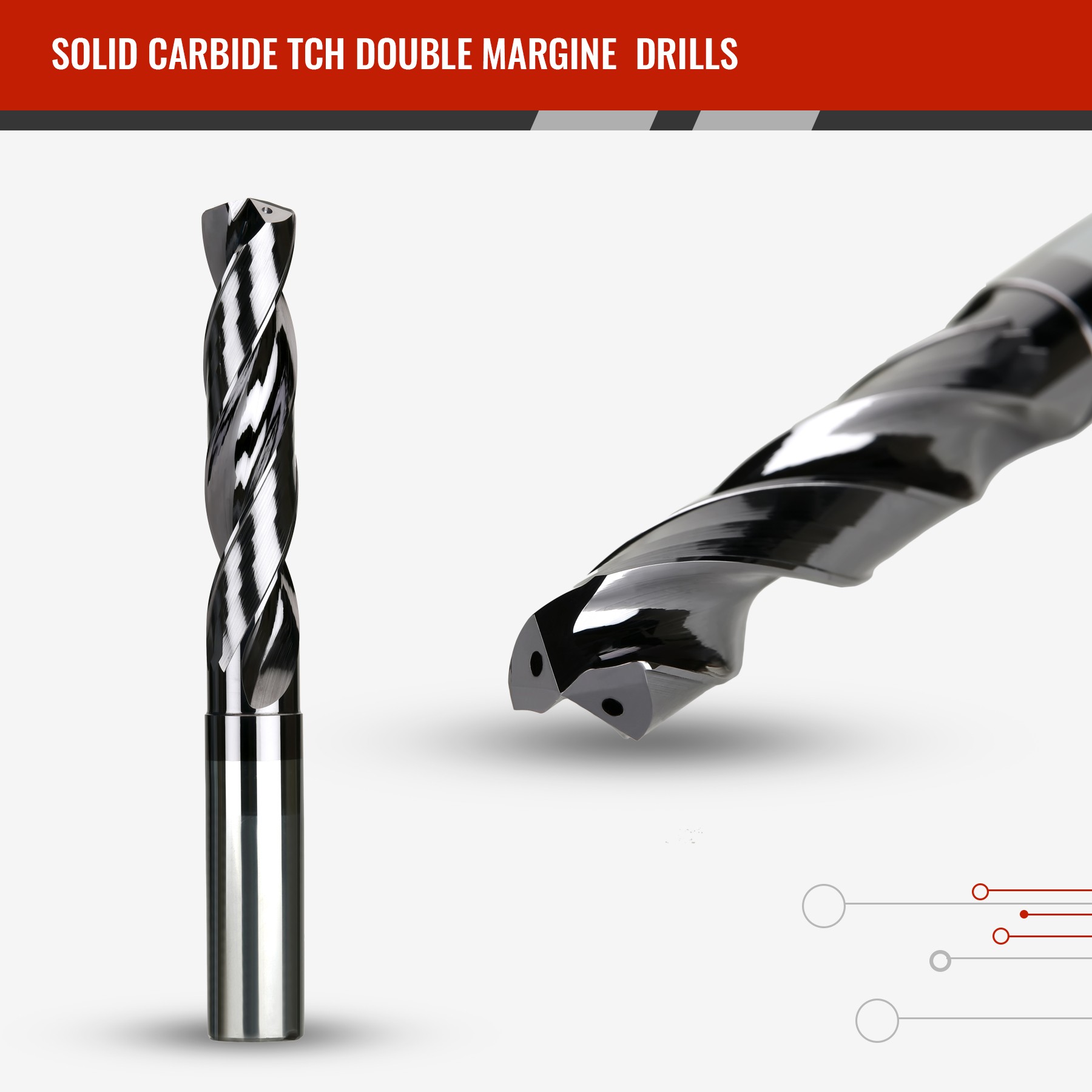

Chip pockets are broad, allowing for superior chip management and evacuation. The new HiPIMS Coating, which is designed specifically for cutting drill, ensures consistent and long tool life in a wide range of work materials and applications. For tiny machines, it provides solid drilling with no wobbling and a better hole finish with a double margin.

Hole guiding regions on two cutting edges enable Accusharp to provide reliable high-quality hole machining in terms of cylindricity and straightness, as well as near hole tolerance, premium surface roughness and production stability.

The toughest and most brittle of the drill bit materials is carbide. It’s mostly utilized for cutting drilling, which necessitates the employment of a high-quality tool holder and equipment. It should not be utilized in drill presses or hand drills. These drill bits are made for the toughest and most demanding materials.

Tips

1) Ensure surface is machined before drilling

2) Use the precision-specific ACCUSHARP Pilot drill for pre-drilling

3) Check for wear on Pilot drill throughout the operation, which can lead to premature tool failure

4) Ensure maintaining coolant pressure and good filtration of coolant